Boland Project

Boland Project

High Grade

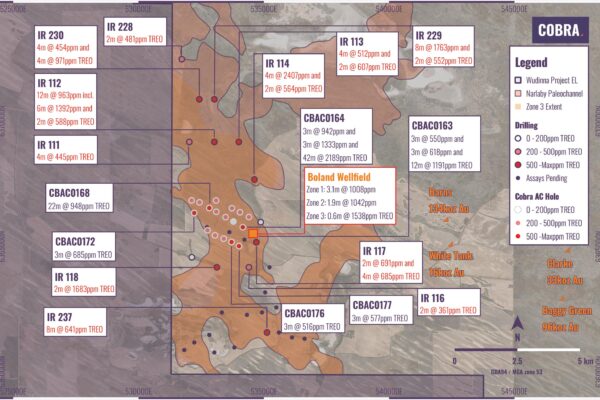

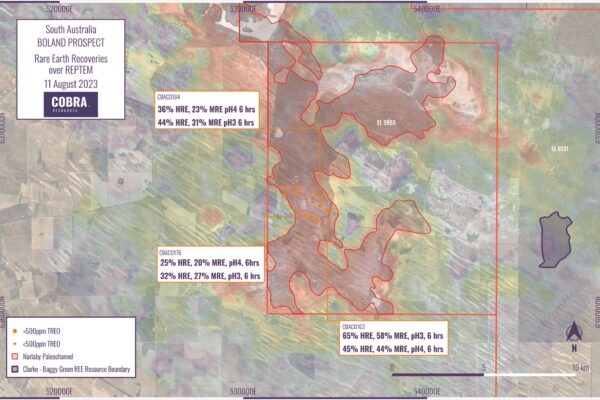

Refined sampling strategy to reflect chemistry boundaries should result in considerable increases of recoverable TREO grades

Scale

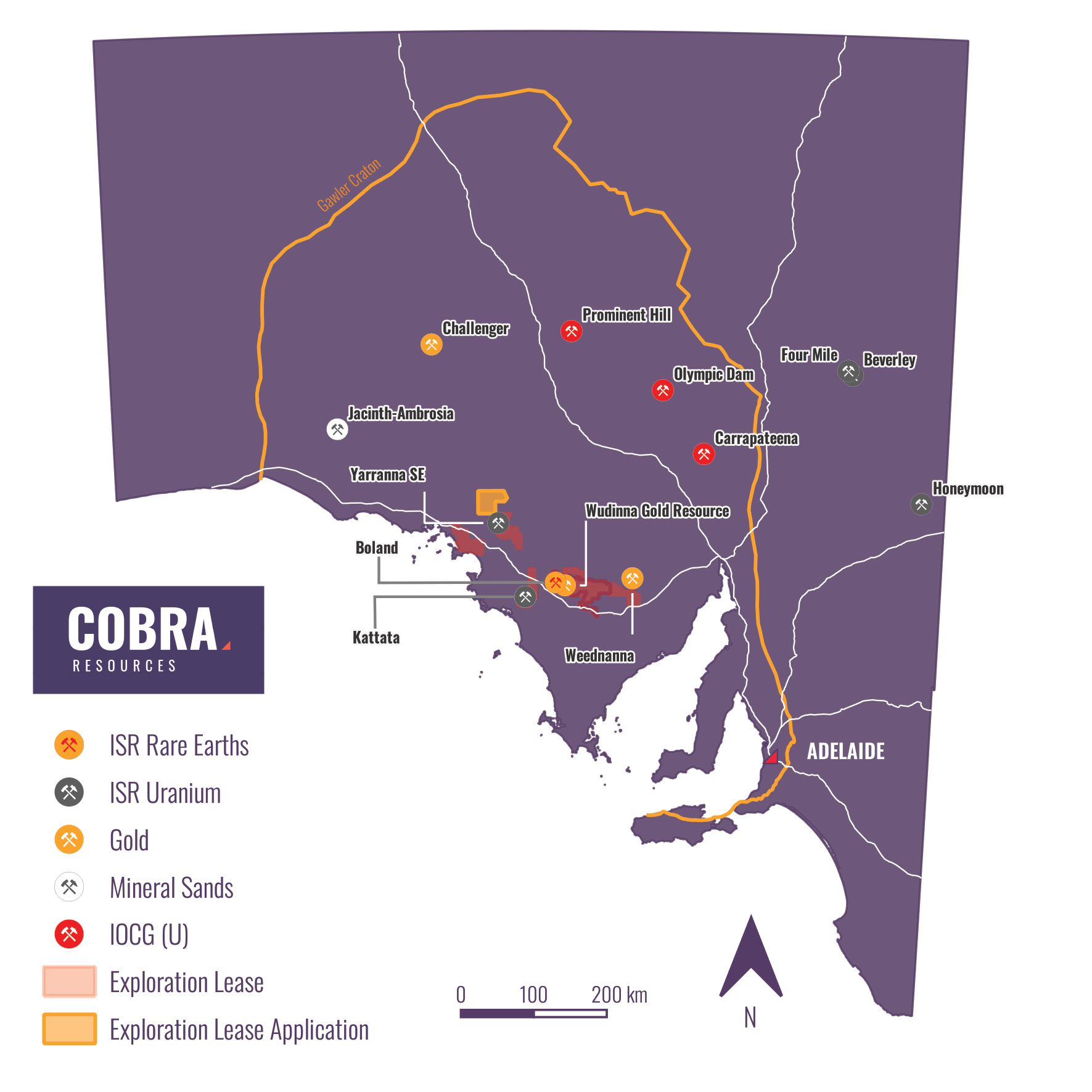

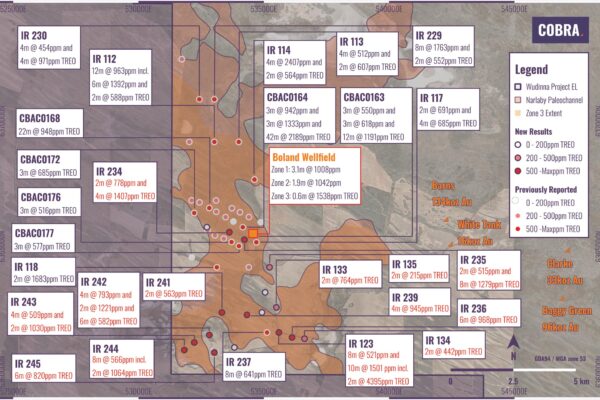

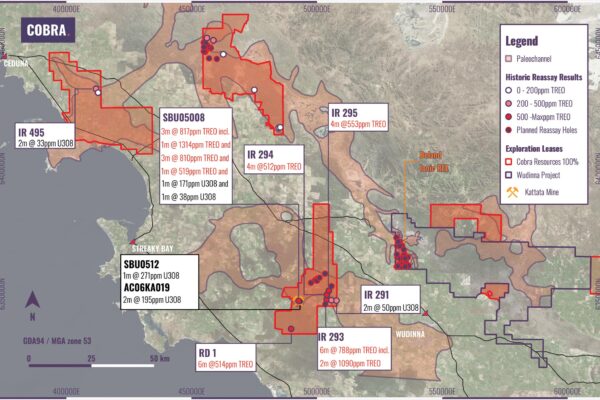

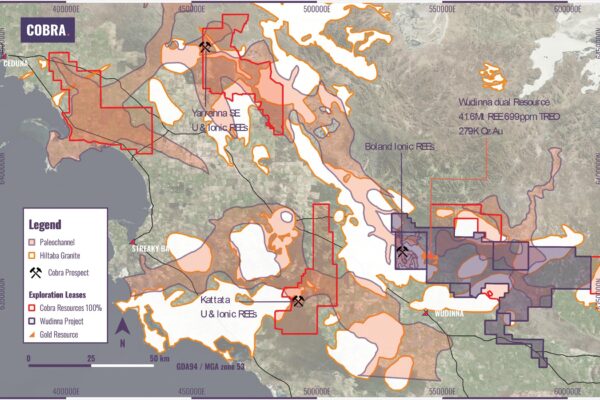

Low-cost approach – over 3,300 km2 of palaeochannel

ISR

Drill plan – fast and cost-effective approach to unlocking long-term value

What is Boland’s Market Advantage?

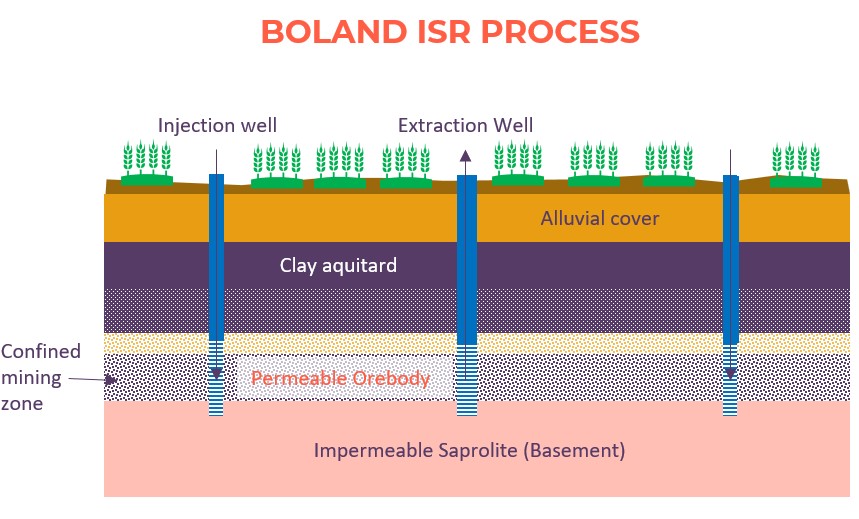

Cobra’s metallurgical work at the Boland Project has demonstrated a remarkably simple and efficient process for extracting rare earth elements. Using a refined in-situ recovery (ISR) approach, the team is achieving strong recoveries of around 66% of total rare earths, while naturally filtering out lower-value elements to focus on the most critical and high-value materials. The process benefits from an exceptionally straightforward flow sheet and a unique aquifer system where the orebody effectively generates its own leaching solution. This means lower costs, reduced environmental impact, and a cleaner pathway to producing the rare earths needed for the global energy transition.

Highlights

- Unique ionic REE mineralisation enriched in Dysprosium and Terbium

- Cobra’s completed work on the Boland discovery has focused on mitigating metallurgical and operational risk. Results support favourable recovery economics

- Laboratory in situ recovery tests yield 66% recoveries with low acid consumption

- Initial high quality, high grade MREC at 62.4% TREO

- Optimisation tests support cost reduction through orebody acid generation and cerium oxidation

- Field hydrology test demonstrates ideal conditions for environmentally sustainable and productive ISR mining – 1.8m/day permeability

- Expanded land position to support scale – working to deliver a scalable resource

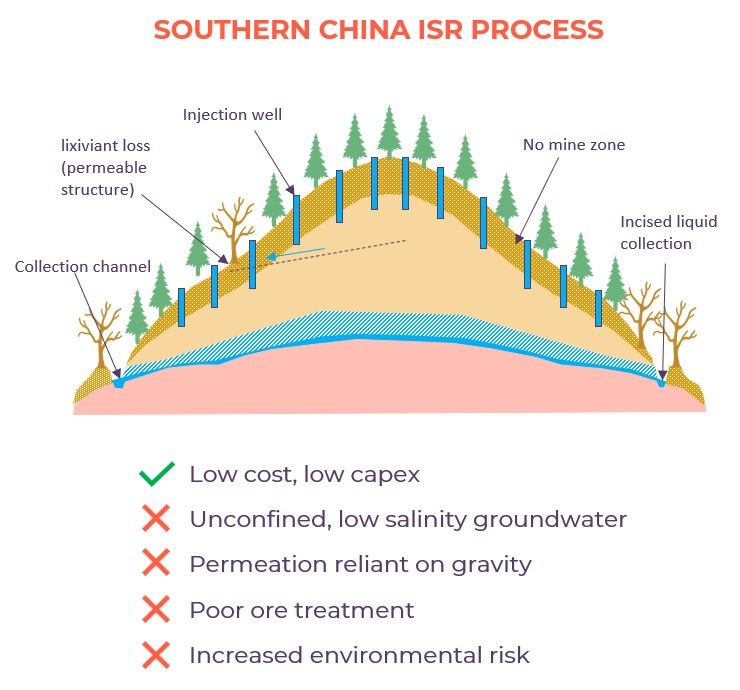

Cobra’s Geology Enables Same ISR Cost Benefits Without the Environmental Risk

ISR processes can vary greatly based on specific geology. ISR ionic rare earth mines in Asia can result in unacceptable damage to the environment. This is due to the unconfined nature of the process.

Mineralisation at Boland has been demonstrated through field testing to be uniquely different to the standard ionic clay mineralisation. Mineralisation occurs in a laterally uniform permeable sand layer that is bound above and below by impermeable aquicludes. This means that lixiviants can be confined to the mineralisation and will not move vertically into overlying and underlying formations mitigating the risk of uncontrolled contamination or loss of lixiviants.

Cobra is working to demonstrate the environmental benefits that can be achieved at Boland, where future pilot studies will work to demonstrate that this mining process can be integrated into existing agricultural land practises.

Boland ISR Process Highlights

- Low cost, low capex

- Confined hyper saline aquifer

- Permeation reliant on permeability

- High treatment

- Low environmental risk